Moving Freight Across New Zealand with Expertise Since 1971

Proven experience, credibility and an unrelenting commitment to meet evolving customer needs – we find the Alexander Advantage to keep our clients ahead of their businesses.

Over 53 years of partnership and continuous innovation, and still ahead of the game.

Over 53 years of partnership and continuous innovation, and still ahead of the game.

Safety Second to None

From the design and specification of our vehicles, to the staff we carefully select to be on our team, safety is at the core of Alexander Group.

Everyone, customers included, is aligned to delivering the safest possible transportation network. This means we are continually reviewing and refining how we manage risk on the road, at customers’ sites and in our own yards. The wellbeing of our staff is a key component to our commitment to safety; robust fatigue management and training programmes are the backbone of our business.

In our pursuit of global best-practice standards, we have a dedicated team at Alexander Group NZ. In partnering with Alexander Group, we will custom design a risk and safety management programme suited to your customers, products and unique supply chains.

We are innovative in our vehicle design aiming to engineer as many safety features as possible into our vehicles, challenging our suppliers to improve on each vehicle build. We also partner with our staff in constantly refining and improving our practices and ensuring staff have access to real time data to manage the changing risks on road in a time-demanding environment.

New Zealand’s most skilled drivers and support staff.

Ongoing investment in best practice technology.

There’s more to that investment than software. Our modern vehicle fleet, specialised for tasks like dangerous goods transport, has been selected from suppliers who align with our vision of best practice in transportation. Our network of service providers are critical to keeping our fleet on the road, and they reach all corners of the country, making us one of the most efficient freight companies New Zealand has to offer.

For 52 years, Alexander Group has been developing, testing, and deploying the best technology to serve its customers, including provisions for the transport of hazardous substances. That investment adds up to a safety, efficiency, and productivity track record that is second to none. This is what makes Alexander Group a top logistics company capable of handling hazardous goods transport and other complex tasks.

Safety Second to None

From the design and specification of our vehicles, to the staff we carefully select to be on our team, safety is at the core of Alexander Group.

Everyone, customers included, is aligned to delivering the safest possible transportation network. This means we are continually reviewing and refining how we manage risk on the road, at customers’ sites and in our own yards. The wellbeing of our staff is a key component to our commitment to safety; robust fatigue management and training programmes are the backbone of our business.

In our pursuit of global best-practice standards, we have a dedicated team at Alexander Group NZ. In partnering with Alexander Group, we will custom design a risk and safety management programme suited to your customers, products and unique supply chains.

We are innovative in our vehicle design aiming to engineer as many safety features as possible into our vehicles, challenging our suppliers to improve on each vehicle build. We also partner with our staff in constantly refining and improving our practices and ensuring staff have access to real time data to manage the changing risks on road in a time-demanding environment.

New Zealand’s most skilled drivers and support staff.

Ongoing investment in best practice technology.

There’s more to that investment than software. Our modern vehicle fleet, specialised for tasks like dangerous goods transport, has been selected from suppliers who align with our vision of best practice in transportation. Our network of service providers are critical to keeping our fleet on the road, and they reach all corners of the country, making us one of the most efficient freight companies New Zealand has to offer.

For 52 years, Alexander Group has been developing, testing, and deploying the best technology to serve its customers, including provisions for the transport of hazardous substances. That investment adds up to a safety, efficiency, and productivity track record that is second to none. This is what makes Alexander Group a top logistics company capable of handling hazardous goods transport and other complex tasks.

Safety Second to None

Safety is at the heart of everything we do at Alexander Group, from vehicle design to the wellbeing of our team. We continuously refine risk management across roads, customer sites, and our facilities, supported by robust training and fatigue management programmes.

Our innovative approach ensures advanced safety features in every vehicle and real-time data empowers our staff to manage dynamic road risks. Partnering with Alexander Group means tailored safety solutions designed to protect your customers, products, and supply chains. Together, we’re building the safest transportation network possible.

New Zealand’s most skilled drivers and support staff

At Alexander Group, our drivers are the backbone of our elite logistics services, ensuring the safe and efficient transport of hazardous substances. Through rigorous training and partnerships with global experts, we equip our team with industry-specific skills, from dangerous goods endorsements to rollover prevention.

Consistently ranked in the top 3-5% of EROAD users globally, our drivers exemplify safety, professionalism, and performance, solidifying Alexander Group as a trusted leader in hazardous goods transport.

At Alexander Group, our drivers are the backbone of our elite logistics services, ensuring the safe and efficient transport of hazardous substances. Through rigorous training and partnerships with global experts, we equip our team with industry-specific skills, from dangerous goods endorsements to rollover prevention.

Consistently ranked in the top 3-5% of EROAD users globally, our drivers exemplify safety, professionalism, and performance, solidifying Alexander Group as a trusted leader in hazardous goods transport.

Ongoing investment in best practice technology

Alexander Group’s telematics and camera-enabled fleet ensures safety, efficiency, and productivity, supported by advanced data analytics. Our modern vehicles, built for tasks like dangerous goods transport, and a nationwide network of service providers keep us running at peak performance.

With 52 years of innovation, we’ve built a track record of excellence in hazardous goods transport and complex logistics, making Alexander Group one of New Zealand’s most trusted freight companies.

Ingrained Innovation

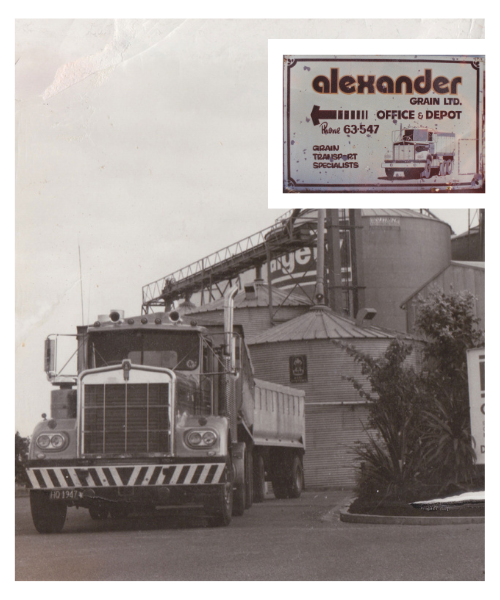

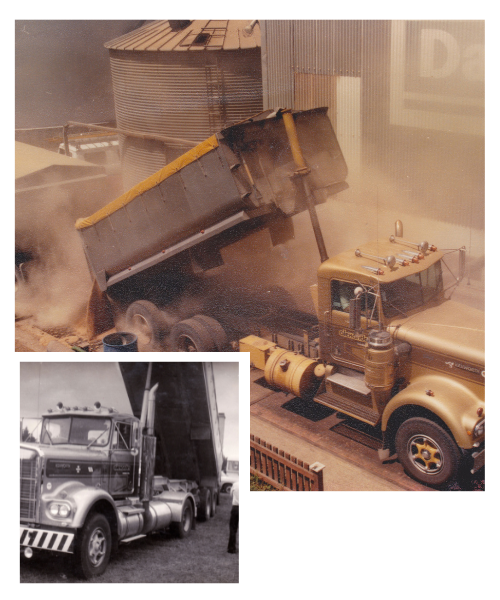

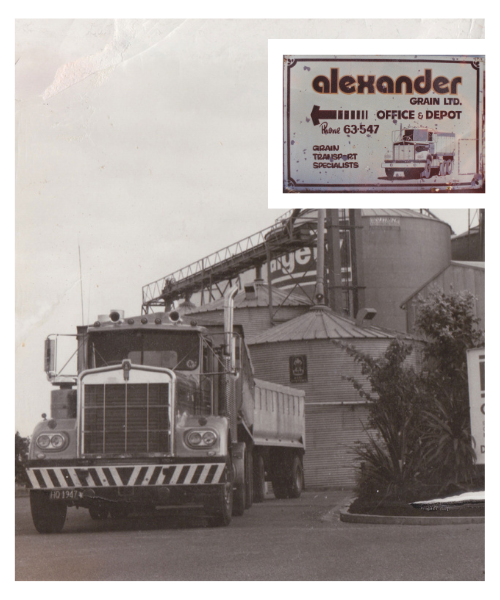

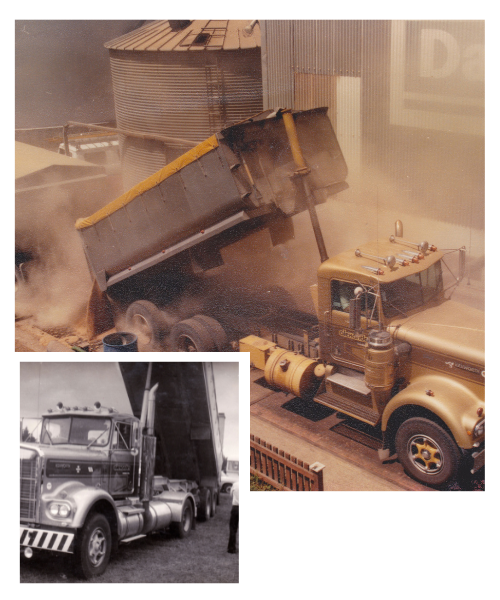

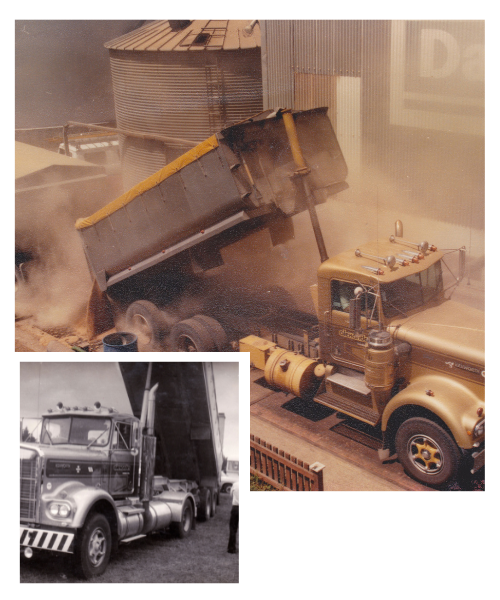

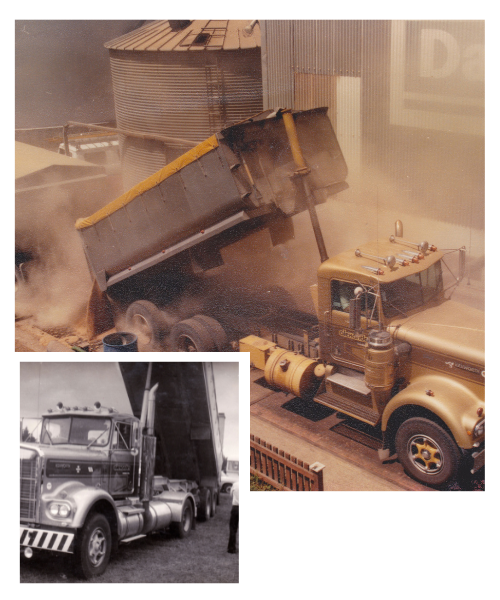

Established in 1971 in Tamahere by John and Cecile, Alexander Group originally specialises in grain transportation, an industry just starting to flourish. By 1976, producers were starting to export – an opportune time for the Alexanders to gain a Gisborne contract to ship 5,000-ton shipments of grain at a time, 24/7 to Mt Maunganui Port. A time of intense growth, it is also a time of innovation: John Alexander invents a hyper-efficient specialist grain unit, later dubbed the ‘Grain Train’. Different to other trucks, it means contents can be bottom-dumped, an invention that helps the young company secure a three-year contract with Northern Roller Milling (now known today as NRM).

%20(1)%20(1).png)

Smarter Cartage

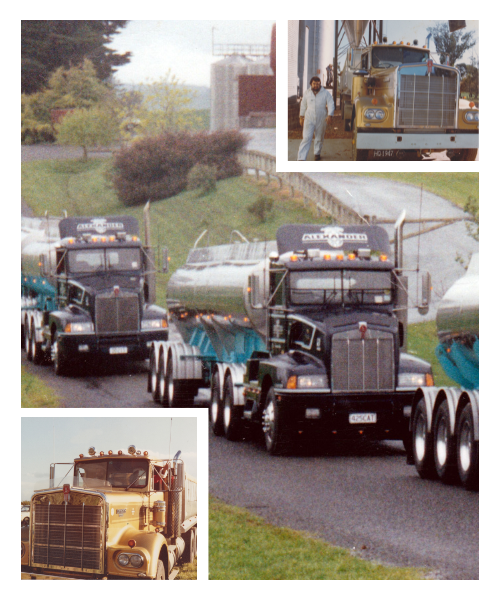

By the late ‘70s, a new Kiwi crop is also beginning to show potential. A call from Jim Delegat of Delegat Wines sees the dawn of Alexander Group’s expansion into the New Zealand wine industry. Carting bulk grapes from Gisborne to Auckland, again an innovative response is called for. Bulk grape is straight off the harvest, tipped straight into the truck. The journey from Gisborne to Auckland means the grapes can be 70% liquid by the time they arrive in Auckland. To solve the issue, the company partners with engineering company Transport and General Ltd developing a special tail board that seals the body of the truck and the tail door, an invention that becomes the future of this type of aluminium truck bodies.

To this day, this innovation is still used in the industry.

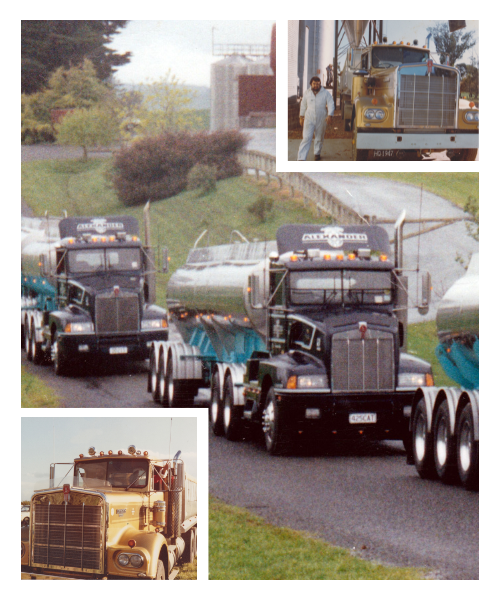

A Bumper Crop

By the mid-80s the grain industry is slowing. Following an extended stint travelling overseas with their young children, the Alexanders return to New Zealand and promptly pick up where they left off, signing a contract with Corban Wines in 1984. This relationship - and those formed with other New World wine pioneers Montana, Delegat, Babich and Nobilo - continues throughout the decade, which sees the company not only responsible for grape cartage, but also finished wine, firmly establishing Alexander Group as a fixture in the viticulture industry.

%20(1).png)

A New Venture

A new decade sees Alexander Group continuing to drive New Zealand’s wine industry forward, with an average of 80-90 million litres of wine and grape juice transported per year. It’s a decade that also sees the fruition of their earlier venture into ethanol cartage. In 1999, conversations with Shell culminate in Alexander Group securing a deal much larger than anything they’ve done before - delivering all of Shell’s retail, commercial, farm, aviation, oil and LPG product in the South Island, setting the wheels in motion for what follows. The 90’s also sees the company acknowledged for its impressive entrepreneurship in 1997, winning the BNZ Small Fleet Operator of the Year Award.

Setting the Standard

The 2000’s is a time of extraordinary agility and responsiveness for Alexander Group. Proving their merit, the company becomes a transport contractor for the South Island, taking over bulk retail delivery and consolidating fuel transport into one 24/7 multi-function fleet with centralised scheduling. Awarded BOC’s South Island bulk distribution in 2002, by 2005 the company also acquires the North Island contract effectively securing all bulk cryogenic gas deliveries throughout New Zealand. Later in the decade, the company establishes the origins of their intermodal arm - a coastal shipping and ISO handling depot in Malborough for wine inter-island transfers. In 2008, Alexander Group is awarded the NZTA Road Transport Innovation and Safety Award.

Continuously Delivering the Goods

By 2012, newly awarded with BOC’s inter-island ISO handling contract, Alexander Group is supplying 100% of BOC’s New Zealand bulk deliveries and Elgas’ South Island LPG deliveries. In rapid succession, in 2013 the company is awarded further BOC distribution contracts in cylinder distribution. In 2014, the White Caps Shipping Service is established, a customised end-to-end domestic and international shipping business. It proves so efficient, an ISO handling depot is set up in Glenbrook to service the Pacific Islands.

%20(1).png)

Ingrained Innovation

Established in 1971 in Tamahere by John and Cecile, Alexander Group originally specialises in grain transportation, an industry just starting to flourish. By 1976, producers were starting to export – an opportune time for the Alexanders to gain a Gisborne contract to ship 5,000-ton shipments of grain at a time, 24/7 to Mt Maunganui Port. A time of intense growth, it is also a time of innovation: John Alexander invents a hyper-efficient specialist grain unit, later dubbed the ‘Grain Train’. Different to other trucks, it means contents can be bottom-dumped, an invention that helps the young company secure a three-year contract with Northern Roller Milling (now known today as NRM).

%20(1)%20(1).png)

Smarter Cartage

By the late ‘70s, a new Kiwi crop is also beginning to show potential. A call from Jim Delegat of Delegat Wines sees the dawn of Alexander Group’s expansion into the New Zealand wine industry. Carting bulk grapes from Gisborne to Auckland, again an innovative response is called for. Bulk grape is straight off the harvest, tipped straight into the truck. The journey from Gisborne to Auckland means the grapes can be 70% liquid by the time they arrive in Auckland. To solve the issue, the company partners with engineering company Transport and General Ltd developing a special tail board that seals the body of the truck and the tail door, an invention that becomes the future of this type of aluminium truck bodies.

To this day, this innovation is still used in the industry.

A Bumper Crop

By the mid-80s the grain industry is slowing. Following an extended stint travelling overseas with their young children, the Alexanders return to New Zealand and promptly pick up where they left off, signing a contract with Corban Wines in 1984. This relationship - and those formed with other New World wine pioneers Montana, Delegat, Babich and Nobilo - continues throughout the decade, which sees the company not only responsible for grape cartage, but also finished wine, firmly establishing Alexander Group as a fixture in the viticulture industry.

%20(1).png)

A New Venture

A new decade sees Alexander Group continuing to drive New Zealand’s wine industry forward, with an average of 80-90 million litres of wine and grape juice transported per year. It’s a decade that also sees the fruition of their earlier venture into ethanol cartage. In 1999, conversations with Shell culminate in Alexander Group securing a deal much larger than anything they’ve done before - delivering all of Shell’s retail, commercial, farm, aviation, oil and LPG product in the South Island, setting the wheels in motion for what follows. The 90’s also sees the company acknowledged for its impressive entrepreneurship in 1997, winning the BNZ Small Fleet Operator of the Year Award.

Setting the Standard

The 2000’s is a time of extraordinary agility and responsiveness for Alexander Group. Proving their merit, the company becomes a transport contractor for the South Island, taking over bulk retail delivery and consolidating fuel transport into one 24/7 multi-function fleet with centralised scheduling. Awarded BOC’s South Island bulk distribution in 2002, by 2005 the company also acquires the North Island contract effectively securing all bulk cryogenic gas deliveries throughout New Zealand. Later in the decade, the company establishes the origins of their intermodal arm - a coastal shipping and ISO handling depot in Malborough for wine inter-island transfers. In 2008, Alexander Group is awarded the NZTA Road Transport Innovation and Safety Award.

Continuously Delivering the Goods

By 2012, newly awarded with BOC’s inter-island ISO handling contract, Alexander Group is supplying 100% of BOC’s New Zealand bulk deliveries and Elgas’ South Island LPG deliveries. In rapid succession, in 2013 the company is awarded further BOC distribution contracts in cylinder distribution. In 2014, the White Caps Shipping Service is established, a customised end-to-end domestic and international shipping business. It proves so efficient, an ISO handling depot is set up in Glenbrook to service the Pacific Islands.

%20(1).png)